In an era where environmental consciousness is paramount, the shift towards sustainable packaging solutions has become a global imperative. Among the ...

READ MOREWeb Menu

Product Search

Exit Menu

Paper Plate Manufacturers

Custom Paper Plate

information to be updated

-

-

The Sustainability Showdown: A Deeper Look The modern conversation around single-use products is dominated by the urgent need for environmental respon...

READ MORE -

1. Introduction to PP Plastic Cup Lid A PP Plastic Cup Lid is a beverage container lid made from polypropylene (PP), a widely used thermoplastic polym...

READ MORE -

In today's fast-paced world, the cold coffee paper cup is more than just a container; it's an integral part of the consumer experience and a critical ...

READ MORE

During the forming process of paper trays, how are the forming temperature and pressure controlled to ensure the uniformity and stability of the paper trays?

When discussing the fine control strategy of forming temperature and pressure in the production process of paper trays in our company, we have to first mention the unique advantages and technological innovations of our product materials, which are the cornerstones for us to stand out in the market and ensure product quality. Our company focuses on packaging solutions that emphasize both environmental protection and efficiency. The PE coating, PLA coating and water-based coating (non-plastic coating) used not only conform to the trend of global sustainable development, but also show excellent stability and safety in performance. PE coating, with its good waterproof and oil-proof properties, ensures the durability of paper trays in various usage scenarios; PLA coating, as a bio-based material, is completely degradable and contributes to environmental protection; and water-based coating, with its non-toxic, harmless and green characteristics, further improves the safety standards of products.

Technical explanation of forming temperature and pressure control

Paper tray forming is a complex process that integrates material science, mechanical engineering and automatic control, in which the control of forming temperature and pressure is particularly critical. They directly determine the physical properties, appearance quality and stability and uniformity of the paper tray in final use. The following are the technical measures and advantages our company has taken in this field:

1. Accurate temperature control system

In order to ensure that the paper tray reaches the ideal physical state during the molding process, we have introduced an advanced temperature control system that integrates high-precision sensors, intelligent algorithms and closed-loop feedback mechanisms. First, through in-depth research on the characteristics of different materials, we set the optimal molding temperature range. On the production line, these sensors monitor the temperature changes of the mold and raw materials in real time and feed the data back to the central control system. The system then automatically adjusts the power output of the heating element according to the preset algorithm to ensure that the temperature fluctuation is controlled within a very small range. In addition, we also use preheating and insulation technology to ensure that the raw materials reach a uniform temperature distribution before entering the molding mold, thereby avoiding deformation or defects caused by uneven temperature during the molding process.

2. Fine pressure control strategy

The molding pressure of the paper tray is directly related to its structural strength and shape stability. Our company uses advanced hydraulic or pneumatic systems, combined with precise pressure sensors and servo control units, to achieve precise control of the molding pressure. During the molding process, the system dynamically adjusts the pressure parameters according to the design specifications, material characteristics and production speed of the paper tray. Through multi-level pressure setting and gradual pressurization, it is ensured that the paper tray can quickly obtain the initial contour shape at the initial stage of molding, and avoids material damage or shape deformation caused by excessive pressure. At the same time, we also pay attention to the uniform distribution of pressure. By optimizing the mold design and adjusting the pressure distribution point, we ensure that the various parts of the paper tray are balanced, and further improve the overall quality of the product.

3. Intelligent production and data analysis

In addition to the above-mentioned physical control methods, our company also makes full use of big data and artificial intelligence technology to comprehensively monitor and optimize the production process. By collecting and analyzing the data of key parameters such as molding temperature, pressure, and production speed, we can timely discover abnormal situations in production, and conduct early warning and intervention. In addition, these data also provide valuable basis for our process improvement and product research and development. For example, by analyzing historical data, we can continuously optimize the setting values of temperature and pressure, find the optimal solution that best suits the current production conditions, and further improve the uniformity and stability of the product.

Comprehensive embodiment of the company's advantages

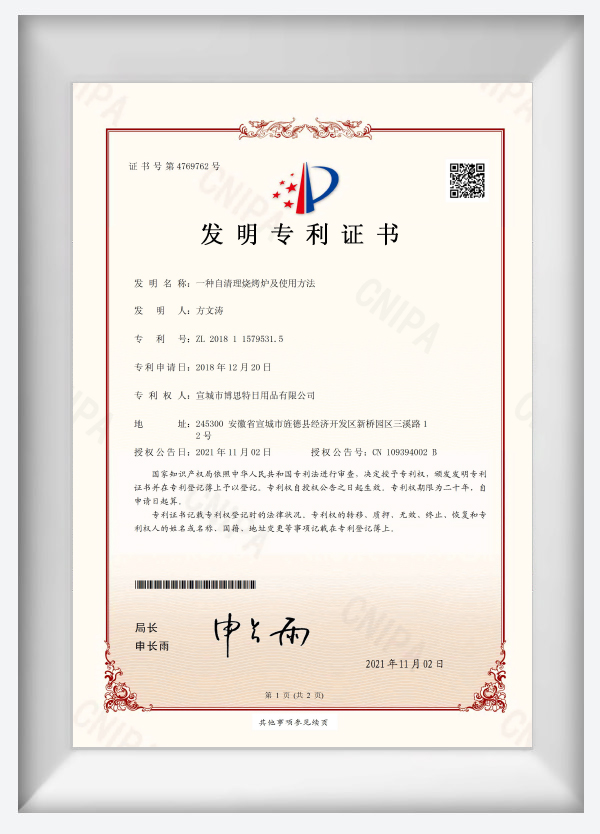

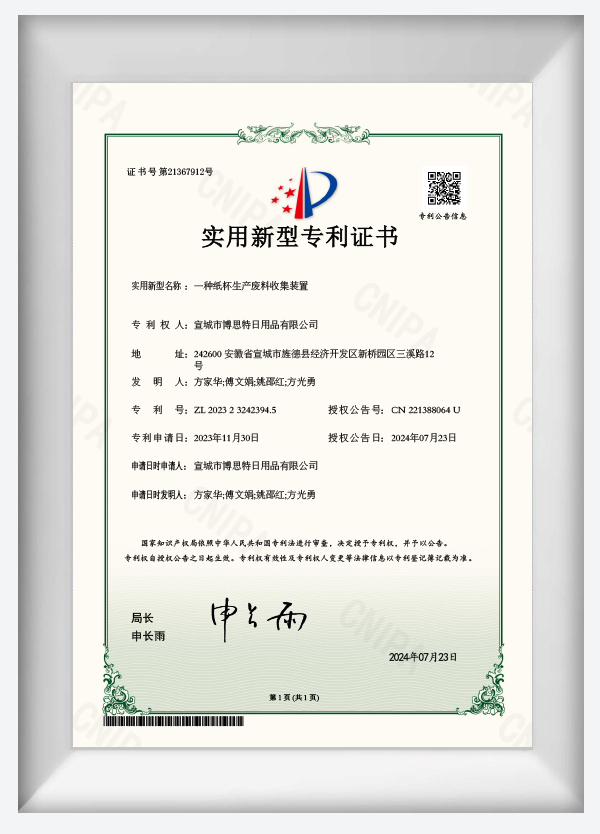

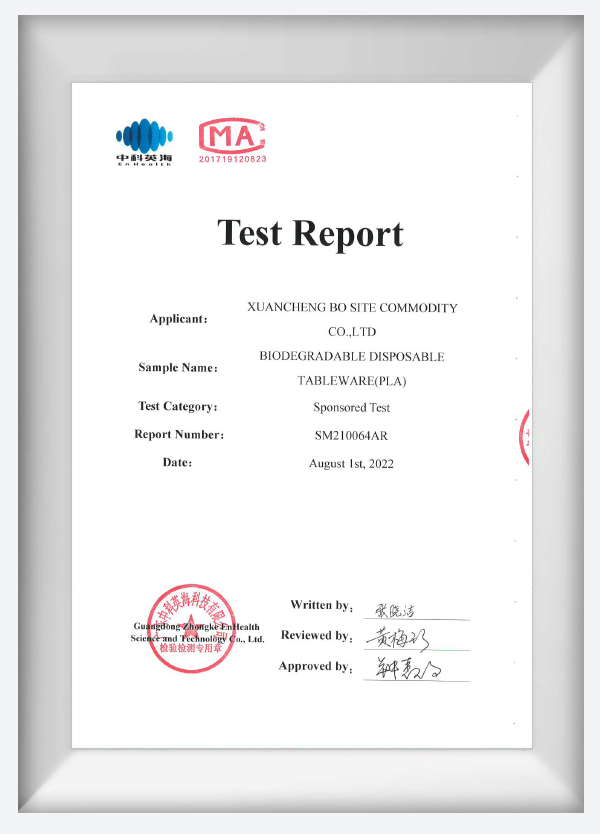

Behind the control of the molding temperature and pressure of the paper tray is our company's unremitting pursuit of technological innovation, quality management and environmental protection concepts. We have 10 valid invention patents and 10 utility model patents independently developed, which not only demonstrates our deep accumulation in the field of technology, but also provides strong support for us to continuously optimize production processes and improve product performance. At the same time, a series of qualification certifications such as the national industrial product production license, sanitation and disinfection license, and printing license, as well as international recognitions such as the EU product safety CE certification and the international forest FSC certification, further prove our outstanding performance in product quality, safety and environmental protection. Through ISO9001 quality management system certification, ISO14001 environmental management system certification and ISO45001 occupational health and safety management system certification, we have built a complete management system to ensure that every link from raw material procurement to product delivery meets the highest international standards.

During the paper tray forming process, our company ensures the uniformity and stability of the paper tray through precise temperature control systems, sophisticated pressure control strategies, and intelligent production management and data analysis, providing customers with high-quality and environmentally friendly packaging solutions. These technical innovations and advantages are the key to our company's leading position in the fierce market competition.

+86-0563-8029081

+86-0563-8029081

+86-0563-8029081

+86-0563-8029081

No. 12 Sanxi Road, Xinqiao Development Zone, Jingde Country, Xuancheng City, Anhui Province.

No. 12 Sanxi Road, Xinqiao Development Zone, Jingde Country, Xuancheng City, Anhui Province.

+86 13856311212

English

English Español

Español عربى

عربى