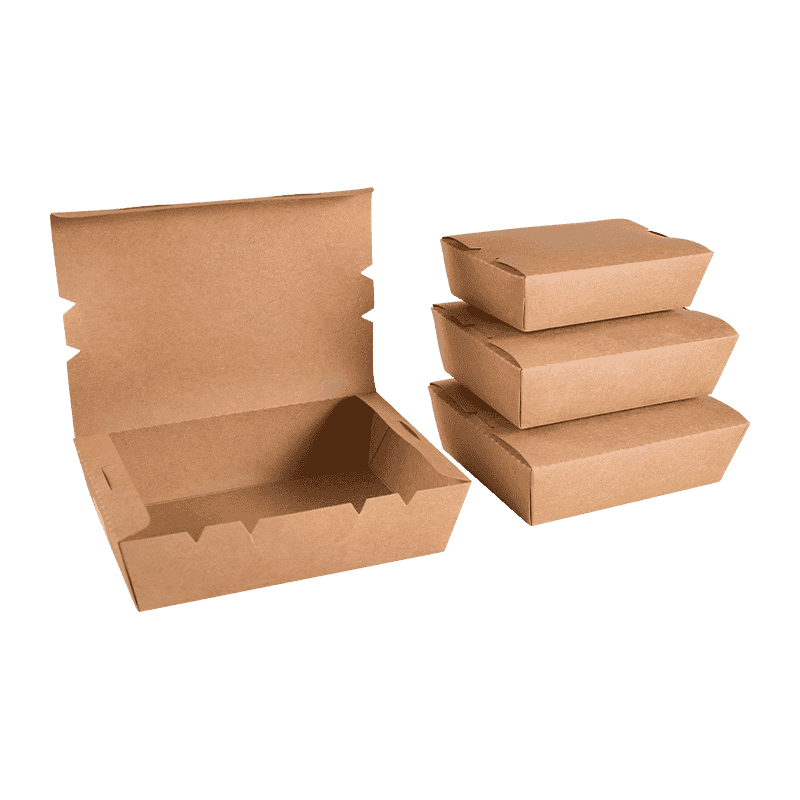

In the rapidly evolving food service industry, packaging is no longer merely a functional necessity; it is a critical component of branding, customer experience, and environmental responsibility. The shift towards sustainable options has propelled kraft takeaway boxes to the forefront, transforming them from a niche product into a global standard. This natural, unbleached material offers a compelling combination of durability, aesthetic appeal, and ecological compliance that resonates with both conscious consumers and forward-thinking businesses. Understanding the material science and operational benefits of these containers is essential for any restaurant, catering service, or food vendor looking to optimize their takeout and delivery operations. The movement is driven by increasing regulatory pressure and a consumer base that actively seeks out brands demonstrating genuine environmental stewardship. The distinctive look of kraft packaging—its natural brown hue and subtle texture—also provides an authentic, artisanal feel that elevates the perceived value of the food inside, signaling quality and care from the moment the customer receives their order.

The Unfolding Popularity of Kraft Takeaway Boxes

The widespread adoption of kraft takeaway boxes represents a paradigm shift away from traditional foam and plastic containers. This change is fundamentally rooted in a global push for sustainability, where businesses are held accountable for their supply chain's environmental footprint. Kraft paper, derived from the chemical pulping of wood, utilizes a less aggressive bleaching process than traditional white paper, preserving the wood's natural strength and requiring fewer harmful chemicals. This process results in a product with superior tear resistance and structural integrity, making it an ideal choice for safely transporting a variety of culinary creations, from hot, saucy entrées to cold salads and desserts. Furthermore, the neutral aesthetic of kraft provides a versatile canvas for branding, offering a clean, rustic look that complements almost any food type. This combination of robust performance and eco-friendliness makes kraft a key differentiator in a crowded market, helping brands communicate their values clearly to their customers. The focus on robust material science ensures that the structural integrity is maintained even when dealing with heavier or moist meals, addressing common pain points associated with lesser-quality packaging.

- Material Superiority: Kraft paper's natural lignin content provides exceptional structural strength, making the boxes less prone to tearing or collapsing under the weight of food.

- Aesthetic Versatility: The earthy, organic look of brown kraft naturally aligns with concepts like farm-to-table, organic, and artisanal foods, enhancing brand storytelling.

- Thermal Performance: Properly constructed kraft containers offer a degree of insulation, helping to maintain the temperature of both hot and cold items during transit.

- Logistical Efficiency: Many designs of kraft takeaway boxes are shipped flat, minimizing storage space requirements and maximizing operational efficiency in busy commercial kitchens.

Environmental Impact: Why Kraft is the Eco-Conscious Choice

The environmental advantage of kraft is perhaps its most compelling selling point, especially in urban markets where sustainability is a primary consumer concern. Unlike polystyrene or non-recyclable plastics, pure kraft paper is sourced from renewable resources, is inherently recyclable, and is biodegradable. However, it is crucial to look beyond the surface and understand the end-of-life cycle of the packaging. When selecting a product, businesses must verify if any coatings, such as polyethylene (PE) or bioplastics like polylactic acid (PLA), are used, as these additives can affect the box's compostability or recyclability in local waste streams. Choosing certified products, often indicated by specific seals, ensures compliance with high environmental standards. This commitment not only reduces landfill waste but also supports the circular economy by reintroducing materials back into the production cycle. For companies aiming for true zero-waste operations, selecting materials that fully decompose without leaving microplastic residue is paramount. The responsible sourcing of the wood pulp, often from managed forests, further reinforces the sustainability narrative, making the choice of kraft a powerful statement of corporate responsibility.

- Renewable Sourcing: The primary material, wood pulp, is a natural, rapidly renewable resource, unlike petroleum-based plastics.

- Lower Energy Consumption: The unbleached process required for natural kraft involves less chemical treatment and consumes less energy and water compared to producing white bleached paperboard.

Compostable vs. Recyclable: Understanding the Difference

Navigating the terminology surrounding eco-friendly packaging can be challenging. While both compostability and recyclability are desirable traits, they refer to distinctly different end-of-life processes. Recyclable materials must be processed at a dedicated recycling facility, often requiring clean separation from food waste. Compostable materials, on the other hand, are designed to break down into non-toxic components, such as water, carbon dioxide, and biomass, ideally in a commercial composting facility within a specific timeframe (usually 90-180 days). For food packaging, compostability is often preferred because it allows the container and residual food scraps to be disposed of together. Businesses should clearly communicate the correct disposal method to their customers to ensure the packaging fulfills its intended environmental benefit. The distinction is not merely semantic; a box labeled 'recyclable' but heavily soiled with food residue may be rejected by recycling plants, whereas a certified 'compostable' box is intended to handle that residual organic matter.

| Feature | Recyclable Kraft | Compostable Kraft |

| Primary Requirement | Clean, dry material; processed at paper mill. | Breaks down into natural elements; requires industrial or home compost environment. |

| Lining Material (if any) | Often PE-lined (can complicate recycling), or no lining. | PLA-lined (certified bioplastic) or vegetable-based coatings. |

| Food Scrap Tolerance | Low; excessive residue may lead to rejection. | High; designed to break down with food residue. |

Functional Excellence: Catering to Modern Takeout Demands

Functional design is the backbone of effective takeout packaging. Modern food delivery services require containers that can withstand the rigors of transportation, prevent leaks, and maintain food quality. Kraft takeaway boxes excel in this area due to their robust construction and the ability to incorporate features like secure locking mechanisms and specialized linings. The clamshell and fold-top designs are particularly popular, providing a secure, tamper-evident seal that assures customers of food safety. Furthermore, the inherent stackability of many kraft designs is a logistical advantage for drivers and restaurant staff, maximizing space efficiency during peak hours. The choice of appropriate box size is also crucial, as oversizing can lead to food shifting and spoilage, while undersizing can compromise the box's integrity. High-quality kraft material minimizes the risk of structural failure, ensuring that the meal arrives in the same condition it left the kitchen. This focus on practical functionality—from easy opening to secure closure—translates directly into improved customer satisfaction and fewer refund requests due to damaged deliveries. The right combination of design and material science ensures a professional and seamless delivery experience.

- Secure Closure: Integrated locking tabs or snap-shut lids offer reliable containment, reducing spills during delivery.

- Venting Options: Some designs feature subtle venting to allow steam to escape, preventing fried foods from becoming soggy while retaining heat.

- Variety of Shapes: Available in shapes tailored for specific items, such as deep-dish boxes for pasta, shallow trays for salads, and clamshells for burgers.

Specialized Kraft Solutions for Every Cuisine

Tackling Sauces and Oils: The Rise of Grease-Resistant Kraft Takeaway Boxes

One of the most significant challenges in food packaging is preventing oil and grease from soaking through the material, which compromises the box's structural integrity and creates a messy experience for the customer. The development of grease-resistant kraft takeaway boxes has directly addressed this issue, enabling restaurants to package even the most oil-rich or saucy meals, such as curries, stir-fries, and fried chicken. This resistance is achieved by applying specialized coatings or linings to the interior of the box. Traditional methods used polyethylene (PE), but increasingly, sustainable alternatives like aqueous coatings or certified food-grade bioplastics (PLA) are being used to maintain the box's eco-friendly credentials. These internal barriers create a hydrophobic surface that repels liquids and fats, keeping the exterior clean and the box sturdy throughout the delivery process. For businesses, this means fewer complaints about messy packaging and a better presentation of their food. The technological advancements in these barriers now allow for full containment of highly saturated items without the trade-off of using non-recyclable materials, demonstrating a harmonious blend of functionality and environmental commitment. This engineering ensures that the aesthetic appeal of the natural kraft is preserved, preventing unsightly oil stains.

- Coating Technologies: Use of safe, certified coatings (e.g., PLA or aqueous) that form an effective barrier against hot oils and liquids.

- Structural Integrity: The grease barrier prevents the softening and weakening of the paper fibers, ensuring the box does not collapse.

| Barrier Type | Grease Resistance Level | Sustainability Impact |

| PE Lining | High | Complicates recycling; not compostable. |

| PLA Lining | Medium to High | Compostable in industrial facilities. |

| Aqueous Coating | Medium | Often fully recyclable and biodegradable. |

Bulk Sourcing and Sustainability: Finding Eco-Friendly Kraft Food Containers Wholesale

For high-volume operations—caterers, chain restaurants, and large meal-prep services—sourcing is a matter of scale, cost, and consistent supply. The search for eco-friendly kraft food containers wholesale focuses on securing competitive pricing without sacrificing the commitment to sustainability. Purchasing wholesale allows businesses to achieve significant economies of scale, making premium, earth-friendly packaging cost-competitive with less sustainable alternatives. However, wholesale buyers must conduct rigorous vetting of suppliers, ensuring that the products are genuinely certified (e.g., FSC certified pulp, BPI compostable certification) and that the supply chain is robust. Volume purchasing is also an opportunity to standardize packaging across multiple locations, reinforcing brand consistency and simplifying staff training on proper assembly and sealing. Strategic sourcing of wholesale containers not only locks in favorable pricing but also provides the peace of mind that comes with a reliable, high-quality, and ethical supply line. Engaging in long-term contracts can also provide pricing stability, protecting against market fluctuations in raw material costs. This is a crucial element of risk management for any enterprise heavily reliant on daily takeout operations.

- Certification Verification: Always request and verify current FSC (Forest Stewardship Council) and composting certifications before making large wholesale commitments.

- Quality Control: Ensure a consistent coating and material thickness across batches to prevent variations in box performance.

Customization and Branding in the Digital Age

Making an Impression: Custom Printed Kraft Takeout Boxes No Minimum Order

In the highly competitive takeout market, branding is everything. Packaging serves as a mobile billboard, extending a restaurant's identity from its physical location to the customer's home. The rise of suppliers offering custom printed kraft takeout boxes no minimum order has been a game-changer for small to medium-sized businesses and start-ups. Previously, custom branding required prohibitively large order volumes, but these new services democratize the process, allowing even a single restaurant to project a polished, professional image. Custom printing typically involves food-safe inks and can range from a simple logo stamp to full-color graphics, allowing for complex and engaging designs that reinforce brand messaging. This flexibility allows businesses to run seasonal campaigns or limited-time promotions using highly branded packaging without incurring massive inventory costs. The natural, earthy tone of the kraft paper provides an excellent background for simple black or single-color prints, creating a striking contrast that is both elegant and cost-effective. Investing in custom packaging is a direct investment in customer loyalty and perceived quality, transforming a necessary expense into a powerful marketing asset. The ability to test different design concepts without a major financial outlay is invaluable for evolving brands.

- Marketing Value: Custom printing elevates the customer's unboxing experience, making the meal feel more special and gift-like.

- Affordability: "No minimum" options make premium branding accessible to local businesses and small-batch food producers.

Practical Features: Ensuring Food Safety with Microwave Safe Kraft Food Packaging

A key feature for customer convenience is the ability to reheat food directly in the container. The demand for microwave safe kraft food packaging has surged, addressing the need for both immediate consumption and safe storage/reheating. Not all kraft containers are safe for microwaving; the key distinction lies in the type of lining used. Boxes featuring a specific grade of PLA or an unlined construction are generally deemed safe, while those with standard PE lining or hidden metal components (like staples) should be avoided entirely in a microwave. Suppliers who offer certified microwave-safe options are providing a significant value-add that can be a deciding factor for customers choosing between delivery options. This feature is particularly valuable for meal-prep services and family-style takeout, where portions are often saved for later. Proper labeling is critical; businesses must ensure that their packaging explicitly indicates its microwave safety to avoid confusion or potential hazards for the customer. This convenience factor directly influences customer satisfaction ratings and repeat business in the fiercely competitive delivery sector, positioning the product as superior and highly functional. The thermal stability of the chosen material is rigorously tested to prevent warping or chemical leaching during the heating process.

- Customer Convenience: Eliminates the need to transfer food to another dish for reheating, simplifying the process for the end-user.

- Safety Assurance: Certified microwave-safe materials prevent the container from warping, leaching chemicals, or causing sparks.

Future-Proofing Your Food Service

The Full Sustainable Cycle: Embracing Compostable Brown Kraft Lunch Boxes

The ultimate goal of sustainable packaging is to achieve a full, circular life cycle where the material returns safely to the earth. Compostable brown kraft lunch boxes represent the pinnacle of this effort. These containers, often certified for both home and industrial composting, ensure that the entire package—including any bioplastic windows or coatings—breaks down naturally. This is the preferred choice for businesses operating in regions with strong organic waste programs, as it ensures that the packaging does not become a contaminant in the recycling stream. The brown kraft appearance naturally communicates this commitment to the environment, aligning perfectly with healthy, organic, or ethical food concepts. By selecting these fully compostable options, businesses not only comply with current and future environmental regulations but also appeal directly to the growing demographic of environmentally conscious diners. This forward-looking packaging strategy is more than just a trend; it is a necessary investment in the planet and the long-term viability of the food service industry. The structural integrity of these boxes is often enhanced to account for the lack of traditional plastic coatings, utilizing a denser paperboard or specialized structural folds to maintain its form factor.

- Zero-Waste Credential: Supports a business's claim to be operating with a truly zero-waste approach for its disposable goods.

- Regulatory Compliance: Positions the business ahead of impending bans on single-use plastics and non-compostable packaging.

FAQ

Are Kraft Takeaway Boxes Truly 100% Biodegradable and Compostable?

The claim of 100% biodegradability and compostability for kraft takeaway boxes is highly dependent on the lining and additives used. Uncoated, pure brown kraft paper is inherently biodegradable and compostable. However, most food-service kraft containers require a grease- or moisture-resistant lining to handle wet and saucy foods. If the box is lined with traditional polyethylene (PE), it is no longer readily compostable, and its recyclability becomes complex due to the mixed material. For a box to be certified compostable, it must use a bioplastic lining, such as PLA, or an aqueous coating, and the entire product must meet stringent standards from certifying bodies like BPI or TÜV. When sourcing, always verify the specific lining material and look for explicit 'Compostable' or '100% Biodegradable' certification marks, not just 'Eco-Friendly,' to ensure the claim is fully accurate. The presence of food residue often complicates the recycling of PE-lined kraft, making certified compostable options a much cleaner and more reliable end-of-life solution for food packaging.

What is the Best Lining Material for Grease-Resistant Kraft Takeaway Boxes?

The "best" lining for grease-resistant kraft takeaway boxes is a balance between performance, cost, and environmental impact. For maximum grease and moisture protection, traditional PE lining is highly effective but hinders both composting and simple recycling. For a sustainable, high-performance solution, a certified PLA (Polylactic Acid) lining is generally considered the optimal choice. PLA is a plant-based bioplastic that provides excellent barrier properties and allows the entire container to be commercially composted. A newer, increasingly popular alternative is the aqueous coating. This coating is a water-based application that offers a good level of grease resistance while allowing the paper fibers to remain fully recyclable and often biodegradable in a home setting. Businesses dealing with extremely oily foods should lean towards PLA for maximum protection, while those prioritizing universal recyclability and a low environmental footprint might prefer the aqueous-coated, fully recyclable grease-resistant kraft takeaway boxes.

How Can Small Businesses Afford Custom Printed Kraft Takeout Boxes No Minimum?

Small businesses can afford custom printed kraft takeout boxes no minimum by utilizing modern digital printing and just-in-time manufacturing offered by specialized packaging suppliers. Unlike traditional offset printing, which requires expensive printing plates and massive initial order quantities, digital printing allows for high-quality, full-color customization with minimal setup costs. This shift eliminates the large inventory overhead and the financial risk associated with a minimum order quantity (MOQ). Small businesses should look for suppliers who specialize in short-run orders and use single-color printing or water-based inks, which are often the most cost-effective methods for customization on a natural kraft substrate. By keeping the design simple—focusing on a single-color logo or a QR code—and utilizing the natural aesthetic of the brown kraft, businesses can achieve a premium, branded look at a low unit cost, making professional packaging accessible for daily operations and special events alike. This agility allows for dynamic, seasonal branding changes without committing capital to large, obsolete stock.

English

English Español

Español عربى

عربى

+86-0563-8029081

+86-0563-8029081

+86-0563-8029081

+86-0563-8029081 No. 12 Sanxi Road, Xinqiao Development Zone, Jingde Country, Xuancheng City, Anhui Province.

No. 12 Sanxi Road, Xinqiao Development Zone, Jingde Country, Xuancheng City, Anhui Province.