In an era where environmental consciousness is paramount, the shift towards sustainable packaging solutions has become a global imperative. Among the ...

READ MOREWeb Menu

Product Search

Exit Menu

PLA Cup Covers Suppliers

Custom PLA Cup Covers

-

Read More

Disposable Leak-proof Plastic PLA Eco-friendly Hot Drink Cup Cover with Straw Cover

Disposable Leak-proof Plastic PLA Eco-friendly Hot Drink Cup Cove...

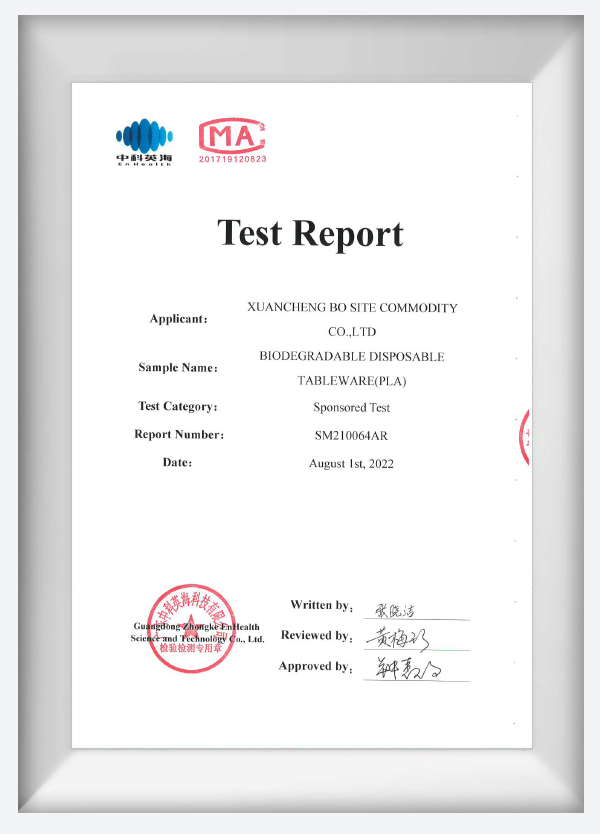

Our PLA Cup Lids focus on environmental sustainability and innovation to offer an usage experience. PLA, or polylactic acid, is a bio-based material derived from renewable plant resources like cornstarch and sugarcane. It is fully biodegradable in natural environments, making it an eco-friendly alternative to traditional petroleum-based plastics. These PLA cup lids are durable and fit snugly onto various beverage cups, preventing spills and ensuring safe transport of your drinks. The unique material properties provide desirable insulation, allowing your hands to feel the desirable temperature, whether enjoying a chilled drink on a hot summer day or a warm beverage in winter, for a comfortable drinking experience. The streamlined design of the PLA cup lid adheres to ergonomic principles, ensuring a comfortable grip and easy operation. Whether drinking directly or using a straw, it adapts effortlessly to various scenarios, meeting diverse usage needs.

-

-

The Sustainability Showdown: A Deeper Look The modern conversation around single-use products is dominated by the urgent need for environmental respon...

READ MORE -

1. Introduction to PP Plastic Cup Lid A PP Plastic Cup Lid is a beverage container lid made from polypropylene (PP), a widely used thermoplastic polym...

READ MORE -

In today's fast-paced world, the cold coffee paper cup is more than just a container; it's an integral part of the consumer experience and a critical ...

READ MORE

How to ensure the quality stability of PLA Cup Covers in large-scale production?

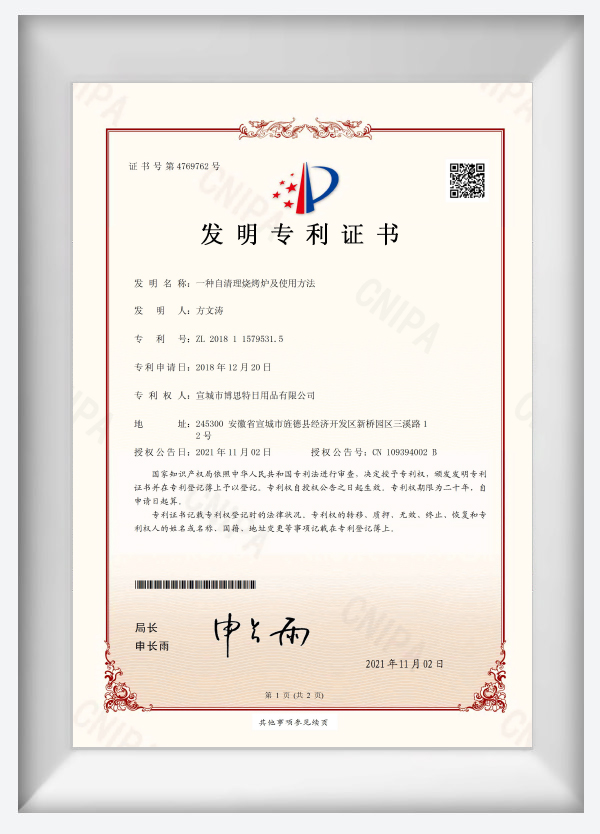

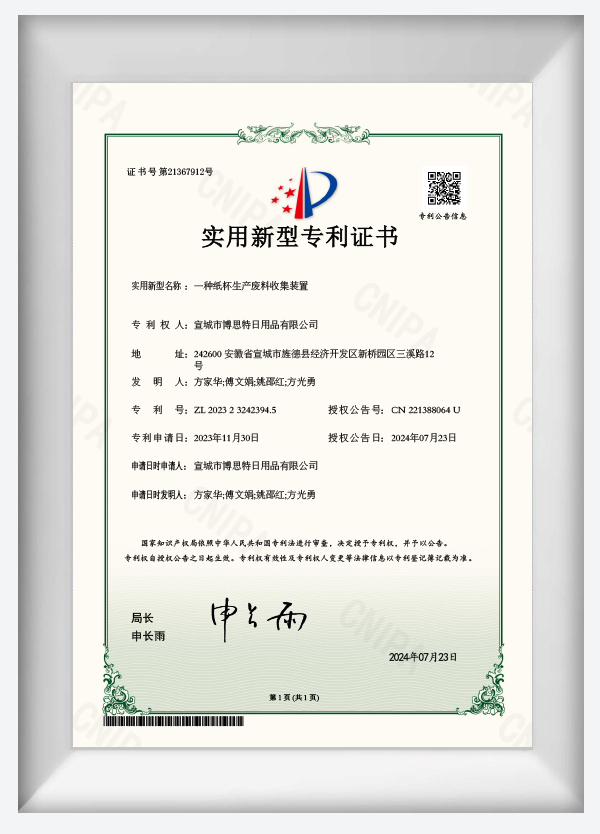

Ensuring the quality stability of PLA Cup Covers in large-scale production is a systematic project involving multiple links and levels. Xuancheng Bo Site Commodity Co., Ltd., as a private technology-based enterprise integrating design, R&D, production, sales and service, especially an enterprise with the honor of high-tech enterprises, will inevitably work hard in the following aspects to ensure the consistent quality of PLA cup covers.

1. Strict quality control system

The company has established a comprehensive quality management system and strictly follows the ISO 9001 international standard. This system runs through every link from raw material procurement, production and processing, finished product inspection to after-sales service. By formulating detailed quality control processes and operating specifications, it is ensured that each step has clear standards and responsible persons, so as to achieve refined management of the entire production process.

2. Advanced production equipment and technology

In large-scale production, advanced production equipment and high-precision production technology are the basis for ensuring the stability of product quality. Our company will invest in automated and intelligent production lines, using high-precision molds, injection molding machines, testing equipment, etc. to reduce the impact of human factors on product quality. At the same time, the production process is continuously optimized to ensure that the PLA material can maintain stable physical and chemical properties during the processing.

3. Quality control of raw materials

As a bio-based material, the quality of PLA directly affects the performance of the final product. Therefore, the company will strictly screen suppliers and choose to cooperate with reputable and stable raw material suppliers. Before the raw materials are put into storage, they will be strictly inspected and tested to ensure that the raw materials meet the established quality standards and environmental protection requirements. The company will also establish a raw material traceability system so that the cause can be quickly located and measures can be taken when problems arise.

4. Continuous process improvement and technological innovation

In the face of the ever-changing market and the increasing diversification of customer needs, the company will continue to invest in R&D resources to improve process and innovate technology. By introducing new technologies, new materials and new processes, the production efficiency and quality stability of products can be improved. At the same time, the company will also establish a process improvement mechanism to encourage employees to put forward improvement suggestions, and reward and promote effective suggestions.

5. Strict product testing and acceptance

During the production process of PLA Cup Covers, the company will set up multiple quality inspection points to conduct comprehensive testing of the products. Including size inspection, appearance inspection, physical property test, chemical property test, etc., to ensure that the product meets the established quality standards and customer requirements. At the same time, before the finished product is put into storage, a final acceptance test will be carried out to ensure that each batch of products is qualified.

6. Employee training and skills improvement

Employees are the key factor in the production process. The company will regularly train employees in quality awareness, operating skills, equipment maintenance, etc. to improve employees' quality awareness and operating skills. Through training and skills improvement, employees can better grasp the key links and precautions in the production process, thereby reducing the impact of human factors on product quality.

7. Continuous improvement and customer feedback

Our company will establish a continuous improvement mechanism, and through collecting and analyzing customer feedback, internal audits, management reviews, etc., we will continuously discover problems and deficiencies in the production process and take measures to improve them. At the same time, the company will also pay attention to industry dynamics and technological development trends, and adjust production strategies and product directions in a timely manner to adapt to market changes.

Xuancheng Bo Site Commodity Co., Ltd. ensures the quality stability of PLA Cup Covers during large-scale production through strict quality control system, advanced production equipment and technology, quality control of raw materials, continuous process improvement and technological innovation, strict product testing and acceptance, employee training and skills improvement, continuous improvement and customer feedback.

+86-0563-8029081

+86-0563-8029081

+86-0563-8029081

+86-0563-8029081

No. 12 Sanxi Road, Xinqiao Development Zone, Jingde Country, Xuancheng City, Anhui Province.

No. 12 Sanxi Road, Xinqiao Development Zone, Jingde Country, Xuancheng City, Anhui Province.

Copyright © 2024 Xuancheng Bo Site Commodity Co., Ltd. All Rights Reserved.

PLA Cup Covers Suppliers

+86 13856311212

English

English Español

Español عربى

عربى