In an era where environmental consciousness is paramount, the shift towards sustainable packaging solutions has become a global imperative. Among the ...

READ MOREWeb Menu

Product Search

Exit Menu

Disposable Kraft Takeaway Boxes Manufacturers

Custom Kraft Paper Takeaway Box

-

Read More

Disposable Environmental Friendly Kraft Paper Takeaway Square Paper Bowl Packaging Boxes

The Disposable Environmental Friendly Kraft Paper Takeaway Square...

-

Read More

Disposable Kraft Biogradable Compostable Food Grade Rectangular Takeaway Paper Bowl

The disposable Kraft Biodegradable Compostable Food Grade Rectang...

-

Read More

Disposable Biodegradable Oil-proof Lunch Boxes

The Disposable Biodegradable Oil-proof Lunch Boxes are crafted fr...

-

Read More

Disposable Environmental Friendly Kraft Rectangular Two Compartment Takeaway Fast Food Packing Boxes

Disposable Environmental Friendly Kraft Rectangular Two Compartme...

-

Read More

Multi Grid Rectangular Octagonal Bowl

The multi-grid rectangular octagonal bowl is carefully made of hi...

Takeaway Kraft Boxes are crafted with a commitment to protecting food and embracing eco-friendly practices. Made from high-quality, eco-friendly kraft paper, these boxes undergo a special process to retain the natural texture and strength of the paper while ensuring each use is safe and reliable. The design of these takeaway kraft boxes is meticulously crafted to accommodate various takeaway foods, from piping hot burgers and fried chicken to delicate sushi and sashimi, providing desirable protection and maintaining the original taste and desirable temperature. The box's desirable sealing prevents leakage of sauces, ensuring that the takeaway food arrives safely in customers' hands. These kraft paper boxes are biodegradable and easy to recycle, reducing environmental impact after use, making them the ideal choice for every consumer who values green living.

-

-

The Sustainability Showdown: A Deeper Look The modern conversation around single-use products is dominated by the urgent need for environmental respon...

READ MORE -

1. Introduction to PP Plastic Cup Lid A PP Plastic Cup Lid is a beverage container lid made from polypropylene (PP), a widely used thermoplastic polym...

READ MORE -

In today's fast-paced world, the cold coffee paper cup is more than just a container; it's an integral part of the consumer experience and a critical ...

READ MORE

How to prevent cracks or deformation of kraft paper during the folding and gluing processes used in the production of takeaway kraft paper boxes?

When discussing the issue of how to skillfully use folding and bonding processes to effectively prevent cracks or deformation of kraft paper during the production of takeaway kraft paper boxes by our company, we had to dig deeper and demonstrate our expertise in technological innovation, material science, and environmental friendliness unique advantages in the production process. The following is a detailed analysis and response strategy for this technical challenge, while incorporating the support of the company's multiple patented technologies and certification systems.

1. Material selection and pretreatment

We understand that material selection is the cornerstone of preventing cracks and deformation. Therefore, the high-quality environmentally friendly kraft paper we choose not only has high strength and good toughness, but has also been treated with a special process to retain its natural texture and enhance tear resistance. In this step, we use self-developed patented technologies (such as the application of specific surface treatment fluids) to significantly improve the durability and folding resistance of kraft paper without affecting its environmental protection properties. These technical details are the reflection of our company's deep accumulation in the field of materials science.

2. Precise design and die-cutting technology

During the design stage, we use advanced CAD/CAM systems, combined with years of packaging design experience, to accurately calculate the position and angle of each crease to ensure uniform stress distribution during the folding process and reduce the risk of cracks caused by improper design. At the same time, in the die-cutting process, we have introduced a high-precision laser die-cutting machine to ensure smooth and burr-free cutting edges, further reducing paper damage caused by friction during the folding process.

3. Innovative folding technology

In the folding process, we innovatively introduced "pre-creasing" technology. This technology pre-presses precise crease lines on the paper so that the kraft paper can be folded smoothly along the preset path during the subsequent manual or automatic folding process, effectively avoiding stress concentration and cracks caused by sudden bending. In addition, we have also optimized the folding sequence and force control, and through repeated trials and adjustments, we have found the most suitable folding solution for our materials to ensure that every takeaway box can be presented in its best condition.

4. Selection and application of environmentally friendly adhesives

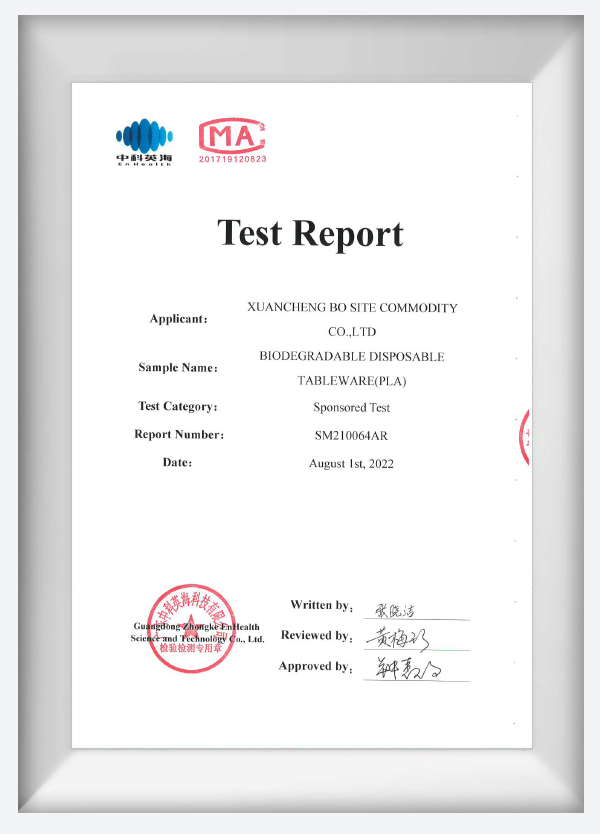

Adhesion is a key link in the production of takeaway kraft cartons, and it is also an important step in preventing deformation. We abandoned traditional adhesives that may contain harmful substances and instead used self-developed water-based environmentally friendly adhesives. This adhesive is not only non-toxic and odorless, and meets food-grade safety standards, but its strong stickiness can ensure that all parts of the carton are tightly bonded, effectively resisting external impact and preventing deformation. At the same time, we use precise coating technology to ensure even distribution of adhesive, which not only reduces the dosage but also improves the bonding effect, further embodying our environmental protection concept and technical strength.

5. Quality control and testing system

To ensure that every link reaches the highest standards, we have established a strict quality control and testing system. From the entry of raw materials to the delivery of finished products, strict quality inspection points are set up at every step, and high-precision testing equipment is used to monitor key indicators such as strength, toughness, and bonding strength of kraft paper in real time. In addition, we also conduct regular production line audits and process optimization to ensure that the production process is always at the forefront of the industry.

Company advantages and certification system support

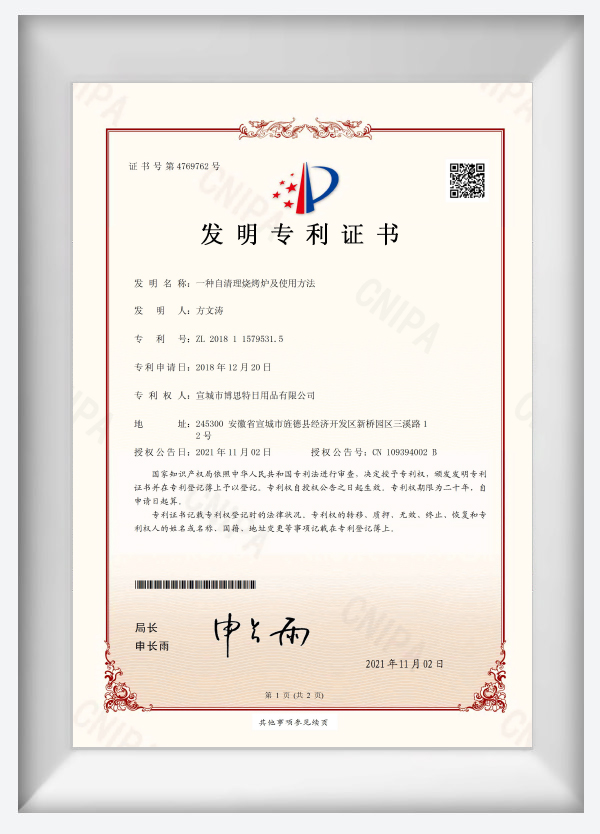

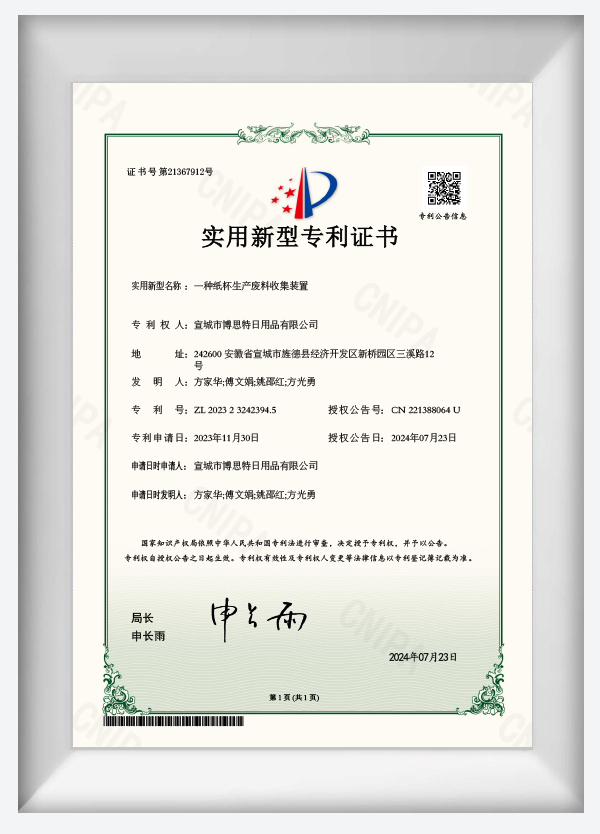

The smooth implementation of the above technical solutions is inseparable from our company's strong technical strength and complete certification system. The 10 valid invention patents and 10 utility model patents we own are not only a direct reflection of our technological innovation, but also provide us with a solid theoretical foundation and practical tools to solve technical problems in production. At the same time, the acquisition of national industrial product production licenses, sanitation and disinfection licenses, printing licenses and other qualifications ensures the compliance of our products within the legal framework.

International certifications such as EU product safety CE certification and international forest FSC certification are high recognitions of our product quality and environmental protection concepts, further broadening our international market. The passing of ISO9001 quality management system certification, ISO14001 environmental management system certification and ISO45001 occupational health and safety management system certification is a comprehensive affirmation of our corporate management level, environmental performance and occupational health and safety capabilities.

In the process of producing takeaway kraft paper boxes, our company has effectively solved the problems in the folding and bonding process of kraft paper through material science, precision design, innovative technology, environmentally friendly adhesives, and strict quality control and testing systems. Possible cracks and deformation problems. The implementation of this series of technical solutions not only demonstrates our leading position in technological innovation, but also reflects our company's deep commitment to environmental protection and social responsibility. In the future, we will continue to adhere to the development concept of "green, innovation, and excellence" to provide safer, environmentally friendly, and high-quality takeaway packaging solutions to consumers around the world.

+86-0563-8029081

+86-0563-8029081

+86-0563-8029081

+86-0563-8029081

No. 12 Sanxi Road, Xinqiao Development Zone, Jingde Country, Xuancheng City, Anhui Province.

No. 12 Sanxi Road, Xinqiao Development Zone, Jingde Country, Xuancheng City, Anhui Province.

Copyright © 2024 Xuancheng Bo Site Commodity Co., Ltd. All Rights Reserved.

Kraft Food Takeaway Boxes Suppliers

+86 13856311212

English

English Español

Español عربى

عربى