In an era where environmental consciousness is paramount, the shift towards sustainable packaging solutions has become a global imperative. Among the ...

READ MOREWeb Menu

Product Search

Exit Menu

Soup Container Manufacturers

Custom Soup Container

-

Read More

Disposable Microwavable Kraft Paper Soup Bowl with Paper Cover

Disposable Microwavable Kraft Paper Soup Bowl with Paper Cover is...

The Soup Container is crafted from premium natural kraft paper, emphasizing durability and a commitment to environmental sustainability. Its unique paper texture exudes a subtle natural aroma, allowing users to savor the warmth and purity of nature while enjoying their soups. We have carefully considered user experience in both carrying and consumption. The container features smoothly finished edges for a comfortable grip that avoids cuts, and a reinforced bottom that provides reliable support, even when filled with steaming hot soups, preventing deformation. Additionally, the unique sealing design effectively retains heat and flavor, ensuring deliciousness and warmth accompany you wherever you go. This kraft paper soup container is fully biodegradable, allowing for easy recycling and minimizing environmental impact. Whether it's for family gatherings, outdoor picnics, or office lunches, it is sure to be a highlight of your dining experience, reflecting your pursuit of quality living.

-

-

The Sustainability Showdown: A Deeper Look The modern conversation around single-use products is dominated by the urgent need for environmental respon...

READ MORE -

1. Introduction to PP Plastic Cup Lid A PP Plastic Cup Lid is a beverage container lid made from polypropylene (PP), a widely used thermoplastic polym...

READ MORE -

In today's fast-paced world, the cold coffee paper cup is more than just a container; it's an integral part of the consumer experience and a critical ...

READ MORE

How to ensure the dimensional accuracy of paper during the slitting process to adapt to the production of soup containers of different specifications?

In the process of exploring how our company ensures the dimensional accuracy of paper to adapt to the production of soup containers of different specifications, we have to deeply analyze every link from raw material selection, processing technology, quality control to finished product inspection, which together constitute a solid foundation for the technological advancement and market adaptability of our products. The following is a detailed explanation of this process, aiming to show our company's outstanding advantages at the technical level and deep concern for the environment.

Raw material selection and pretreatment

We are well aware that the quality of raw materials is one of the key factors that determine the performance of the final product. For soup containers, the use of high-quality natural kraft paper as the substrate not only reflects our commitment to durability and environmental sustainability, but also lays a good foundation for the subsequent processing process. During the raw material procurement stage, we strictly screen suppliers to ensure that each batch of kraft paper meets international environmental standards and has excellent physical properties and stable dimensional stability.

In the pre-treatment stage, we use advanced paper processing technology, including humidity regulation, temperature control and flattening treatment, to eliminate the stress and deformation that may occur during the production and transportation of paper, and ensure that the paper achieves the best dimensional stability and flatness before entering the slitting process. This step is crucial to the improvement of subsequent slitting accuracy.

High-precision slitting technology

1. Application of advanced equipment

In order to achieve high-precision control of paper size, we have introduced internationally leading automated slitting equipment. These equipment are equipped with high-precision servo motor drive systems, laser ranging sensors and advanced control systems, which can achieve precise control of paper length, width and angle, and the error range can be controlled at the micron level. At the same time, the equipment supports multiple programming modes, and can quickly adjust cutting parameters according to the needs of different specifications of soup containers, improving production efficiency and flexibility.

2. Intelligent control system

Our slitting equipment also integrates an intelligent control system, which automatically adjusts cutting parameters by real-time monitoring of paper conveying speed, tension changes and cutting tool wear to ensure the stability of paper size throughout the production process. In addition, the system also has fault warning and remote diagnosis functions, which can detect and deal with potential problems in a timely manner, reduce downtime, and improve production efficiency and product quality.

3. Precision tools and maintenance

The accuracy and state of the tools directly affect the slitting effect. We use high-quality alloy tools, which are precision-processed and heat-treated to ensure that the blades are sharp, wear-resistant and stable in size. At the same time, we have established a strict tool maintenance system, regularly inspecting, grinding and replacing the tools to ensure that they work in the best condition, thereby ensuring the continuous stability of the slitting accuracy.

Quality control and inspection

During the slitting process, we implemented strict quality control measures. First, we set up an online quality inspection point and used high-precision measuring instruments to monitor the size of the paper after slitting in real time to ensure that each piece of paper meets the preset specifications. Secondly, we have established a complete quality traceability system to number and record each batch of products so that when problems arise, they can be quickly traced back to the source and effective measures can be taken to solve them.

In addition, we also regularly calibrate and maintain the slitting equipment to ensure the accuracy and stability of the equipment. At the same time, we organize technical personnel to conduct skill training to improve the team's professional quality and operating skills, and provide strong guarantees for the production of high-quality products.

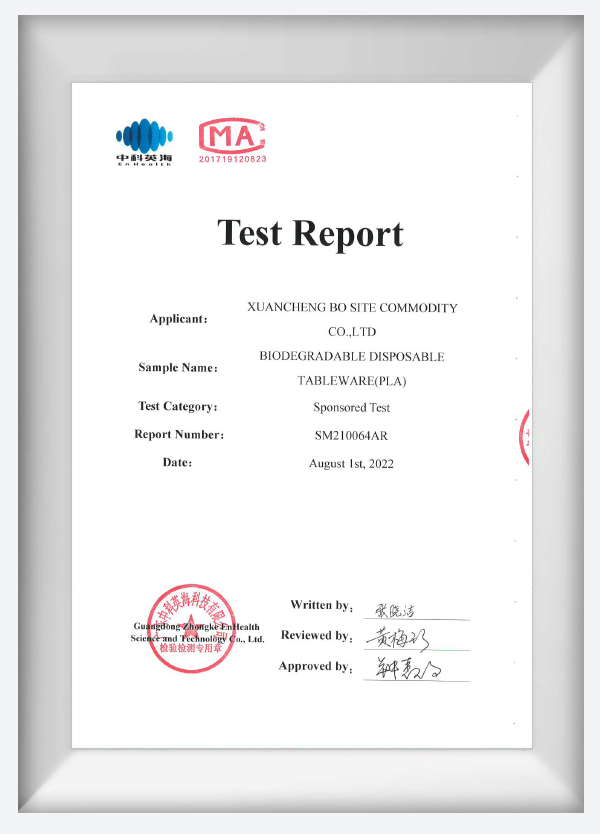

Environmental friendliness and sustainable development

While pursuing technological advancement, we never forget our responsibility to the environment. Our kraft paper soup containers not only focus on energy conservation and emission reduction and resource recycling during the production process, but also can be completely biodegradable and easily recycled after the product is used, minimizing the impact on the environment. This environmental protection concept runs through our entire production process, including the paper slitting process. We use environmentally friendly coolants and lubricants to reduce pollution to the environment; at the same time, by optimizing the slitting process and improving equipment efficiency, we reduce energy consumption and waste generation.

In the production process of soup containers, our company ensures high-precision control of paper size by selecting high-quality raw materials, applying high-precision slitting technology, implementing strict quality control, and adhering to environmentally friendly principles, thereby meeting the production needs of soup containers of different specifications. These technical efforts not only enhance the market competitiveness of our products, but also reflect our unremitting pursuit of technological innovation and environmental protection. In the future, we will continue to uphold this concept, continuously promote technological progress and product upgrades, and provide global consumers with a better quality and environmentally friendly dining experience.

+86-0563-8029081

+86-0563-8029081

+86-0563-8029081

+86-0563-8029081

No. 12 Sanxi Road, Xinqiao Development Zone, Jingde Country, Xuancheng City, Anhui Province.

No. 12 Sanxi Road, Xinqiao Development Zone, Jingde Country, Xuancheng City, Anhui Province.

Copyright © 2024 Xuancheng Bo Site Commodity Co., Ltd. All Rights Reserved.

Soup Container Suppliers

+86 13856311212

English

English Español

Español عربى

عربى