In an era where environmental consciousness is paramount, the shift towards sustainable packaging solutions has become a global imperative. Among the ...

READ MOREWeb Menu

Product Search

Exit Menu

Cardboard Food Tray Manufacturers

Custom Cardboard Food Tray

-

Read More

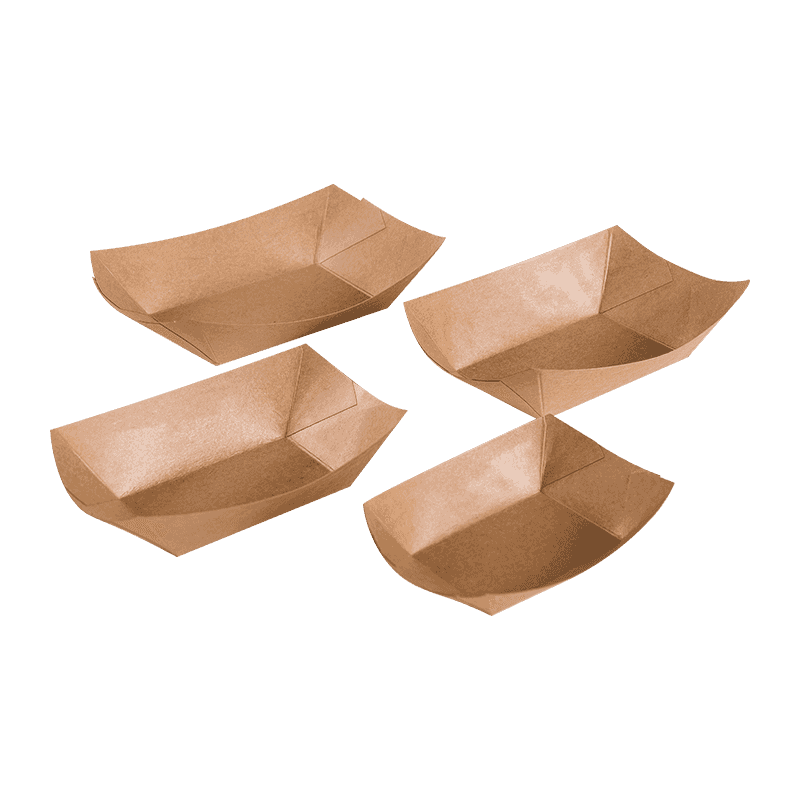

Disposable Food Takeaway Fried Chicken and Fries Snack Kraft Paper Boat-shaped Tray

Disposable Food Takeaway Fried Chicken and Fries Snack Kraft Pape...

-

Read More

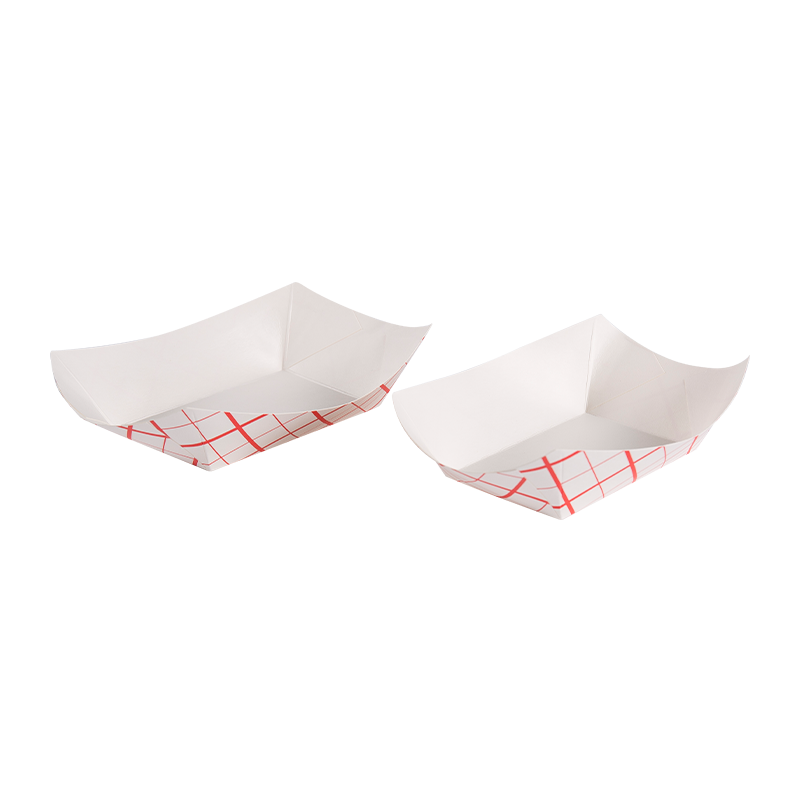

Disposable Red Lattice Oil-proof Kraft Paper Boat-shaped Box Fast Food Paper Tray

The Disposable Red Lattice Oil-proof Kraft Paper Boat-shaped Box ...

The Cardboard Food Tray is meticulously designed for food packaging, combining natural, eco-friendly, and practical features to win over the market. Crafted from high-quality kraft paper as the primary material, it not only retains the paper's flexibility and strength but also imparts a sense of rustic warmth, aligning with modern desires for health and sustainable living. The tray undergoes a special treatment process to ensure no harmful chemical residues are left behind, making it safe for direct contact with all types of food, from fresh produce to baked goods, safeguarding the dietary safety of you and your family. Its unique structural design enhances load-bearing capacity, enabling it to securely hold even the heaviest ingredients without deformation during transport, effectively preserving food quality. Additionally, the kraft paper tray's breathability and moisture resistance extend the freshness of food, making flavors last longer. Its biodegradable and recyclable nature aligns with green environmental principles, offering easy disposal and reduced environmental impact, making it the ideal choice for catering, supermarket retail, and home kitchens.

-

-

The Sustainability Showdown: A Deeper Look The modern conversation around single-use products is dominated by the urgent need for environmental respon...

READ MORE -

1. Introduction to PP Plastic Cup Lid A PP Plastic Cup Lid is a beverage container lid made from polypropylene (PP), a widely used thermoplastic polym...

READ MORE -

In today's fast-paced world, the cold coffee paper cup is more than just a container; it's an integral part of the consumer experience and a critical ...

READ MORE

Do dried cardboard food trays need additional post-processing steps, such as trimming, hot pressing, etc., to improve their final quality and appearance?

When exploring whether dried cardboard food trays need additional post-processing steps, such as trimming, hot pressing, etc., to further improve their final quality and appearance, we have to deeply analyze the technical characteristics of the company's products, the production process, and the market's demand for high-quality food packaging. As a company with deep technical accumulation and extensive certification in the field of food packaging, our company not only pays attention to the environmental protection and safety of materials in the production process of cardboard food trays, but also strives to ensure that the products meet or even exceed customer expectations through refined post-processing processes.

Technical content analysis

Material selection and basic processing

First of all, we use high-quality kraft paper as the main material, and this choice itself contains multiple advantages. Kraft paper, with its natural fiber structure, gives the tray good flexibility and strength, while retaining the unique simplicity and warmth of paper, which perfectly fits the modern consumer's pursuit of health and sustainability. In the basic processing stage, the paper is carefully selected and pre-treated to ensure that there are no impurities and the fiber is evenly distributed, laying a solid foundation for subsequent processing.

Drying process

Drying is one of the key steps in the production of paperboard food trays. It effectively removes excess moisture from the paper and enhances the stability and durability of the tray. However, simple drying is not enough to meet all performance requirements, especially when it comes to further improving the appearance quality, load-bearing capacity and moisture-proof and breathable properties, the post-processing step is particularly important.

Trimming and finishing

Trimming: After drying, the edge of the tray may produce burrs and unevenness due to uneven water evaporation or mechanical cutting. Therefore, we use advanced trimming equipment to finely grind or cut the edge of the tray to ensure smooth and burr-free edges, improve the overall aesthetics and safety of the product. This process not only enhances the tactile comfort of the tray, but also avoids physical damage to the food during the packaging process.

Hot pressing shaping: In order to further enhance the load-bearing capacity and structural stability of the tray, we introduced hot pressing shaping technology. By precisely controlling the temperature and pressure, the pallet is softened and reshaped by heat in a specific mold, thereby eliminating internal stress and optimizing the structural layout. The shape of the pallet after hot pressing is more regular, and the load-bearing capacity is significantly improved. Even if it encounters bumps during transportation, it can effectively maintain the stability and safety of food. In addition, hot pressing can also improve the moisture resistance of the pallet to a certain extent and extend the shelf life of food.

Surface treatment

In addition to trimming and hot pressing shaping, we may also perform special treatments on the surface of the pallet according to customer needs, such as coating PE, PLA or water-based coating (non-plastic coating). These coatings not only enhance the waterproof and oil-proof properties of the pallet, but also improve its aesthetics and durability. In particular, our water-based coating, as an environmentally friendly material, not only meets international environmental standards, but also gives the pallet a more delicate feel and visual effect without affecting food safety.

Company advantages and technology integration

Independent research and development and patent support

The company has 10 valid invention patents and 10 utility model patents independently developed. These patent results are directly applied to all aspects of the production line, from material formulation to process control, reflecting the company's technological innovation capabilities. Especially in the post-processing process, we continue to optimize and upgrade to ensure that every step of the operation is accurate and efficient, and maximize product quality.

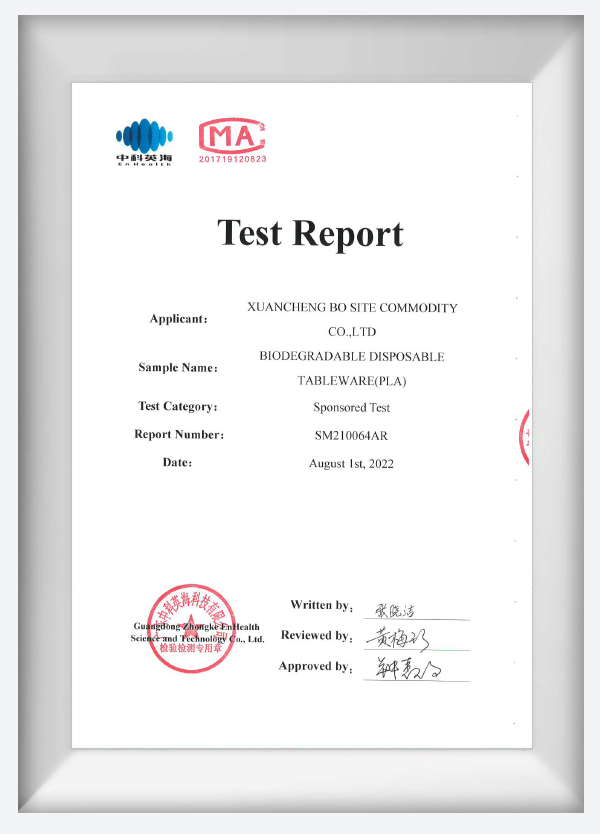

Comprehensive certification and quality assurance

National industrial product production license, sanitation and disinfection license, printing license, foreign trade operator registration, EU product safety CE certification, international forest FSC certification and ISO9001, ISO14001, ISO45001 three management system certification, this series of authoritative certification is not only a recognition of the company's product quality, but also our commitment to continue to pursue excellence, pay attention to environmental protection and safety. In the post-processing process, we strictly abide by various standards and specifications to ensure that every step of the operation meets the highest international standards.

Green environmental protection and sustainable development

As a responsible enterprise, we are well aware of the importance of environmental protection and sustainable development. Therefore, in the production and post-processing of cardboard food trays, we always adhere to the green concept, use biodegradable and recyclable materials, and reduce the impact on the environment. At the same time, by optimizing the production process, reducing energy consumption and emissions, we strive to achieve a win-win situation of economic and environmental benefits.

After drying, the cardboard food tray does need to undergo post-processing steps including trimming, hot pressing and shaping to further improve its final quality and appearance. With the company's technological advantages, comprehensive certifications and green environmental protection concepts, we are confident that we can provide customers with better quality, safer and more environmentally friendly food packaging solutions.

+86-0563-8029081

+86-0563-8029081

+86-0563-8029081

+86-0563-8029081

No. 12 Sanxi Road, Xinqiao Development Zone, Jingde Country, Xuancheng City, Anhui Province.

No. 12 Sanxi Road, Xinqiao Development Zone, Jingde Country, Xuancheng City, Anhui Province.

Copyright © 2024 Xuancheng Bo Site Commodity Co., Ltd. All Rights Reserved.

Cardboard Food Tray Suppliers

+86 13856311212

English

English Español

Español عربى

عربى