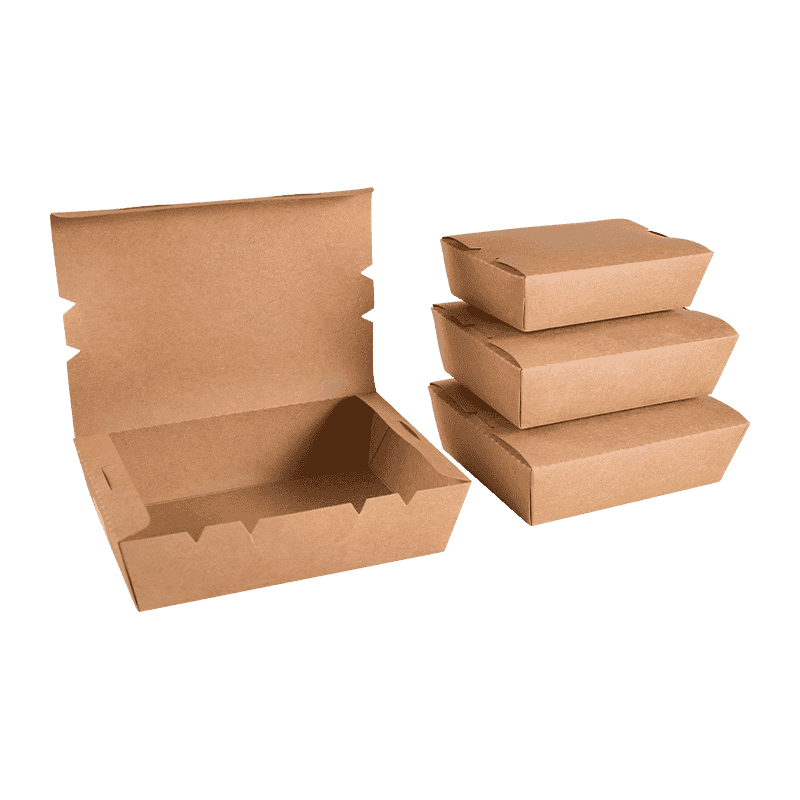

What Are takeaway boxes and Why They Matter

Definition & Material Composition

- takeaway boxes are food-service containers made from paperboard, often one-piece fold-style, used for take-out and delivery.

- The material composition typically includes virgin or recycled paperboard plus an interior coating (PE, PLA or water-based) to provide grease and moisture resistance.

Key Benefits for Food-Service Businesses

- Durability: Strong board resists collapse or soggy bottoms under load.

- Brand image: brown gives a rustic, eco-friendly impression.

- Sustainability: Many boxes now offer compostable or recyclable options.

- Operational convenience: Lightweight, stackable, easy to fold and pack.

How to Choose the Right takeaway boxes bulk supplier

Supplier Credentials & Certifications

- Confirm that the supplier holds food-contact material approvals and relevant certifications (e.g., ISO 9001, ISO 14001, FSC, CE).

- Check manufacturing capacity: ability to handle bulk orders with consistent output.

Minimum Order Quantities, Lead Times, Pricing Comparison

- Bulk orders often require higher minimums but deliver lower unit cost.

- Lead time matters: production, printing, coating, die-cutting all add time.

- Compare total landed cost: unit price + shipping + customs + duties.

Comparison Table: Domestic vs Overseas Bulk Suppliers

| Aspect | Domestic Supplier | Overseas Supplier |

| Unit cost | Higher | Lower |

| Lead time | Shorter | Longer |

| Quality control | Easier local oversight | Requires remote QC or third-party inspection |

| Shipping cost | Lower for local | Higher international freight |

Exploring eco-friendly takeaway boxes with PLA coating

What is PLA Coating & How It Differs from PE

- PLA (polylactic acid) is a bioplastic derived from renewable resources such as corn starch.

- PE (polyethylene) is conventional plastic coating derived from petroleum.

- PLA coating allows for compostability and a more eco-friendly profile; PE is durable and well-proven but less sustainable.

Environmental Impact & Certifications

- PLA-coated boxes may carry certifications such as compostability, bio-based content, etc.

- Companies increasingly require FSC-certified board, non-plastics or minimal plastics, water-based inks.

Comparison Table: PLA versus PE versus Water-based coating

| Coating Type | Environmental Profile | Cost & Performance |

| PLA | High – renewable, compostable | Moderate cost, good performance under moderate heat |

| PE | Low – fossil-based plastic | Lower cost, excellent barrier performance |

| Water-based coating (non-plastic) | Very high – minimal plastics | Higher cost, newer tech, barrier may vary |

The Role of custom printed takeaway boxes for restaurants in branding

Printing Methods and Customisation Options

- Flexographic printing, offset printing, UV printing are common methods.

- Options include full-colour branding, single-colour, soy-based inks, embossing, foil stamping.

- Custom sizes, shapes, compartments to match menu items.

Design Considerations – Size, Logo, Colour, Finish

- Choose a size that fits your portion (e.g., 6"×8"×3", 8"×11"×3").

- Ensure your logo and branding placement is clear and visible even when box is closed.

- Finish options (matte, gloss, spot UV) affect perception and cost.

Comparison Table: Off-the-shelf vs Custom Printed Boxes

| Aspect | Off-the-Shelf Boxes | Custom Printed Boxes |

| Branding | Minimal or none | High – customised logo/graphics |

| MOQ | Low | Higher due to plates/dies |

| Cost per unit | Lower | Higher |

| Distinctiveness | Less | More |

Ensuring Food Safety: Using food grade takeaway boxes microwave safe

Food Grade Materials & Coatings

- Ensure the paperboard is certified food-contact safe (FDA or equivalent jurisdiction).

- Interior coatings must not leach harmful substances when in contact with hot/greasy food.

- Certifications such as sanitary disinfection license, printing license, etc add credibility.

Microwave & Leak-resistance Requirements

- Microwave safe means the box withstands typical reheating without releasing fumes or collapsing.

- Leak resistance matters for saucy or oily food items; coating or barrier must prevent seepage.

Checklist for Food-Service Use

- Check wall thickness and fold integrity of the box.

- Verify coating type (PE/PLA/water-based) and suitability for hot food.

- Confirm stackability and secure lid design (to prevent spills in delivery).

- Ensure supplier offers food-service grade certification.

Looking Ahead: takeaway boxes biodegradable non-plastic coating and sustainability trends

Non-Plastic Coating Options & Industry Standards

- Water-based coatings are emerging as alternatives to plastic films.

- Certifications such as FSC (Forest Stewardship Council), CE, ISO 14001 give assurance of sustainable practices.

- Consumers increasingly look for packaging labelled compostable or biodegradable.

Market Trends & Consumer Expectations

- More restaurants and food chains demand packaging with minimal plastic or plastic-free barrier.

- Regulatory pressure in certain regions is accelerating move away from single-use plastics.

- Eco-friendly packaging can be a differentiator for brands.

Comparison Table: Traditional vs Non-Plastic Coated Boxes

| Feature | Traditional Plastic-Coated Box | Non-Plastic Coated Box |

| Barrier Material | PE or PP film | Water-based or PLA film |

| Compostability | Low | Higher |

| Cost | Lower | Higher |

| Consumer Perception | Standard | Premium / Eco |

Why Choose Xuancheng Bo Site Commodity Co., Ltd for Your takeaway boxes

Company Profile & Production Capabilities

Founded in 2008, Xuancheng Bo Site Commodity Co., Ltd. is honoured as one of the Anhui Province high-tech enterprises and Anhui Province specialized new small and medium-sized enterprises. The company integrates design, R&D, production, sales and service as a private science & technology enterprise. Located in the beautiful millennium town of Jingde County, Anhui Province, west of Huangshan, east of Jiangsu/Zhejiang/Shanghai, north of Wanjiang, transportation is convenient.

The company now operates automatic flexographic printing machines, UV offset printing machines, automatic die-cutting machines, and more than 50 sets of medium and high-speed paper cup machines, plus more than 40 molds for paper cups and paper bowls, with an annual production capacity of 1 billion pieces. While the core capacity described is for paper cups/paper bowls, the company’s scale and serious investment in print and production equipment signals strong capabilities for packaging products such as takeaway boxes.

Quality Certifications & Global Export Markets

The company’s product material covers PE coating, PLA coating and water-based coating (non-plastic coating). It holds 10 effective invention patents and 10 effective utility model patents. Certifications include national industrial product production licence, sanitary disinfection licence, printing licence, foreign trade operator registration, EU product safety CE certification, international forest FSC certification. The company has also passed ISO 9001 quality management system certification, ISO 14001 environmental management system certification and ISO 45001 occupational health & safety management system certification.

Products are mainly sold to Europe, America, the Middle East, South America and other regions, and also provide high-quality paper cups, bowls and other paper containers for large domestic catering chain enterprises and some airlines. This export experience indicates reliability and global-standard manufacturing — a strong plus when sourcing your takeaway boxes.

How the Company Meets Each Long-Tail Keyword Demand

- For the keyword takeaway boxes bulk supplier — the company’s billion-piece annual output supports bulk supply.

- For eco-friendly takeaway boxes with PLA coating — the company offers PLA coating and water-based coating options.

- For custom printed takeaway boxes for restaurants — with UV offset and flexographic printing machines, custom print runs are clearly supported.

- For food grade takeaway boxes microwave safe — the company holds food-contact and sanitary licences, supports food-service grade container production.

- For takeaway boxes biodegradable non-plastic coating — with water-based coating and FSC certification, the company supports eco-friendly biodegradable packaging lines.

Conclusion & Key Takeaways

In today’s competitive food-service packaging market, choosing the right takeaway boxes is more than just picking a container — it’s about durability, sustainability, branding and cost-effectiveness. By working with a reliable bulk supplier that offers eco-friendly coatings, custom printing, food-grade compliance and global export competence, you can secure a packaging solution that checks all boxes.

Your next step should be to evaluate your order volume (bulk requirement), define your coating requirements (PE vs PLA vs water-based), decide on custom printing needs, confirm food-safety certifications and then select a supplier like Xuancheng Bo Site that aligns with those criteria.

English

English Español

Español عربى

عربى

+86-0563-8029081

+86-0563-8029081

+86-0563-8029081

+86-0563-8029081 No. 12 Sanxi Road, Xinqiao Development Zone, Jingde Country, Xuancheng City, Anhui Province.

No. 12 Sanxi Road, Xinqiao Development Zone, Jingde Country, Xuancheng City, Anhui Province.